'The Combing Work', c1750. Textile workers combing or carding wool

Combing: Normally combing processes is done for producing smoother, finer, stronger, and more uniform yarns. The carded materials (sliver) contain a certain amount of short fibers, neps, fine kitty, and leaf particles. At present, it is an important process of spinning.

Demonstration of Hand Combing Wool with Antique Combs

The online group classes are available for textile technology students and individuals who wants to earn knowledge before settling up their start-up (textile business) Sunday, February 9, 2020.. " The combing is a process which eliminates the short fibres, impurities, naps, immature fibres from the sliver, straightens the fibres and make.

100Mile Wear Cleaning fibre with wool combs Rambouillet

Combing in textile is the final proportion of the fiber cleaning process that removes the short fibers, naps, and other impurities such as vegetable matter and seed coat fragments in cotton that has already been carded. Objectives of combing

Basic Concept of Combing Process Types of Comber Machine Textile

Combing. Even though today combing is carried out with modern technologies, it is still based on the same old principles. Combing in the textile field is a process that usually follows carding, and is necessary in order to prepare a semi-finished product for subsequent spinning to obtain combed yarns.. Put simply, a pile of silk fibres is passed through several combs.

The Inconsequential Blogger Flax to linen experiment breaking

Combing or carding is a primary process, followed by the gilling process, which removes hooks and involves three separate machines. Combing is then followed by two Gillings to remove irregularity in the sliver and randomize fibre ends. This post-combing process is required if spinning is to follow.

100Mile Wear Cleaning fibre with wool combs Rambouillet

Textile Basic Knowledge | Combing | part 07 | Learn Textile#textile #basic #knowledgepart 01: https://youtu.be/-vG-W1vZj8Qpart 02: https://youtu.be/A39MaFGpG.

Noble Comb Wool combing machine in the textile gallery at … Flickr

The combing section is an insertion of mostly three machines into the normal spinning process between card and draw frame. This needs more space with conditioned atmosphere which is becoming more and more expensive. It serves as additional system to improve yarn quality if the carded yarn does not meet requirements.

Demonstration of Hand Combing Wool with Antique Combs

Introduction Combing is a crucial process in the textile industry that plays a significant role in enhancing the quality of fibers. It involves the removal of short fibers, impurities, and neps from the raw material, resulting in smoother, stronger, and more lustrous yarns.

100Mile Wear Cleaning fibre with wool combs Rambouillet

Definition of Textile Combing. The combing process is carried out in order to improve the quality of the sliver coming out of the card. The process eliminates short fibres, it achieves better parallelization of fibres, it straightens curls, and it removes neps and residue impurities. The combing process is essentially aimed at obtaining.

COMBING AND SEMI COMBING PROCESS Dilube

EGELSBACH, Germany — December 16, 2021 — Comber machines from Trützschler are already trusted by customers across the textiles industry and around the globe. Now, a state-of-the-art new design is building on this track record to boost productivity, ensure quality and support increased automation: Meet the TCO 21! Higher productivity.

Wool Combing OVWSG

The combing process is normally used to produce smoother, finer, stronger and more uniform yarns. Therefore, combing is commonly confined to high grade, long staple natural fibers. In recent years, combing has been utilized for upgrading the quality of medium staple fibers.

Textile Adviser WORKING PROCEDURE OF COMBING MACHINE AND FEED STOCK

Combing is a textile process that refines fiber by removing impurities and short strands, resulting in a smoother, stronger yarn. This meticulous method enhances fabric quality, ensuring garments are soft to the touch and durable. Intrigued by how combing transforms raw fibers into luxurious textiles?

This is a Combing Machine. Combing is optional, but is used to remove

Combing is an intermittent operation carried out between carding and drawframe. The combing process is normally used to produce smoother, finer, stronger and more uniform yarns. The carded materials (sliver) contain certain amount of short fibers, neps, fine kitty and leaf particles.

How Cotton Fabric Is Made Carding & Combing Cotton Vision Linens

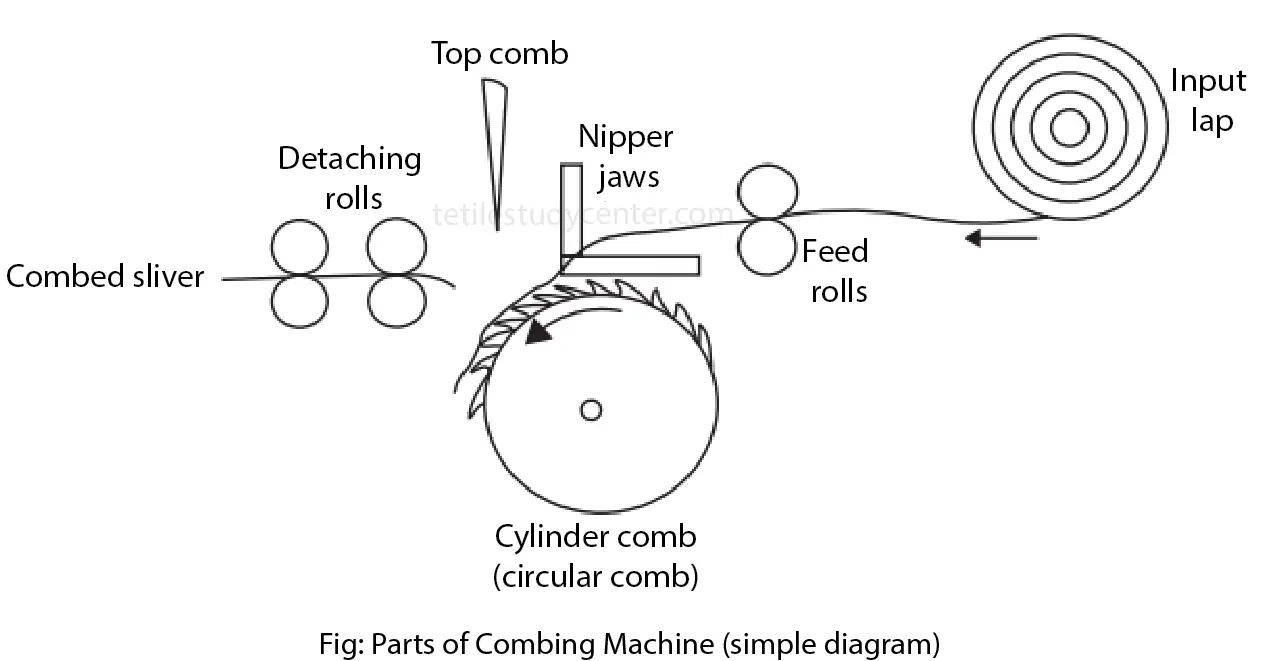

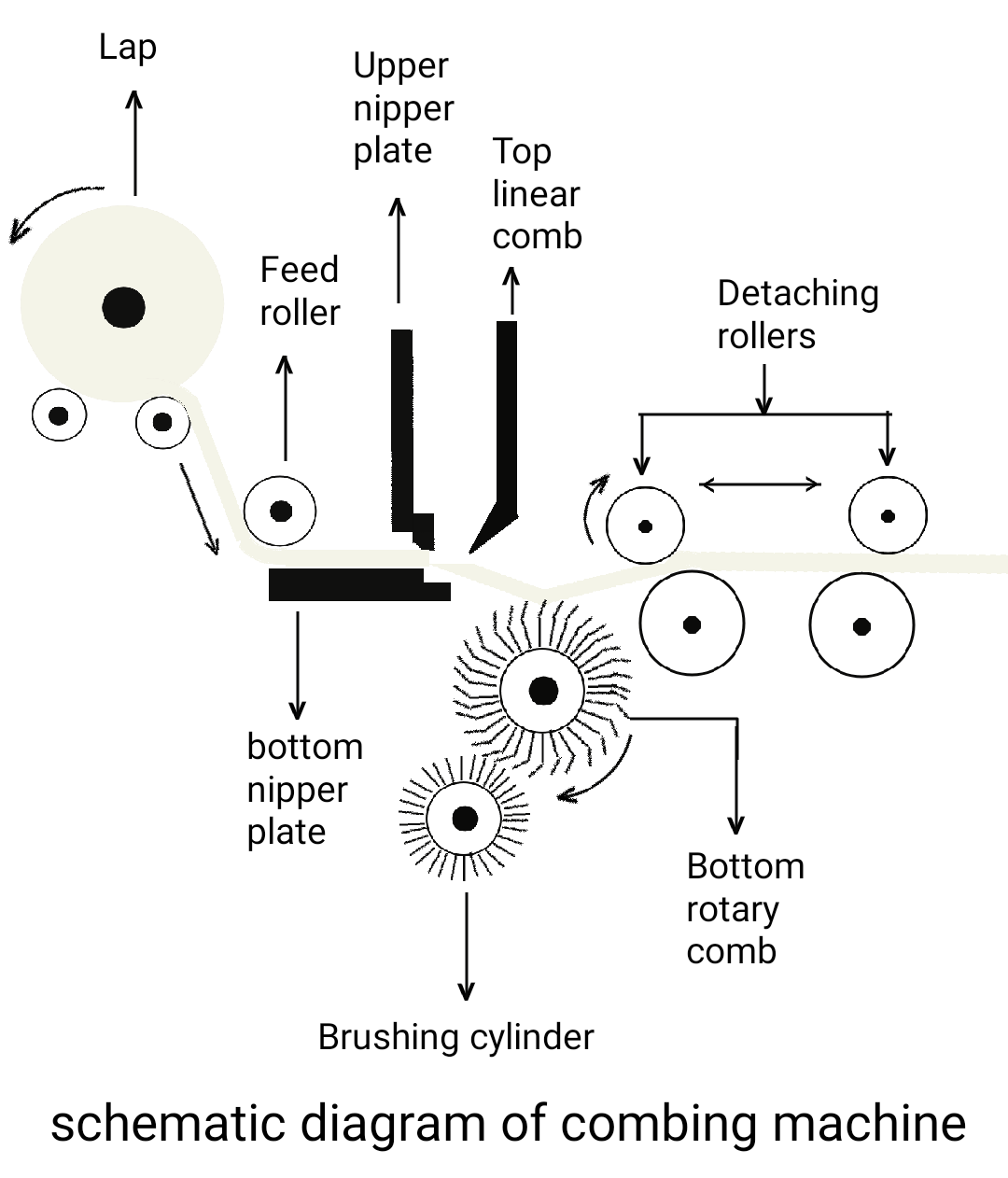

Basic Working Elements of a Combing Machine. The web rolled off from the lap (1) is pinched between the lower (4) and the upper clamp (5). The circular comber covered with combing segments (7) combs out the fiber beard that is protruding from the clamps. The short fbers that are now sticking in the circular comber are removed from the combing.

Combing Textile Craft

Other articles where combing is discussed: textile: Treatment of raw fibre:.desired, carding is followed by combing, a process that removes short fibres, leaving a sliver composed entirely of long fibres, all laid parallel, and both smoother and more lustrous than uncombed types. Slivers may be loosely twisted together, forming roving.

EWESPECIAL Wool Combing

Definition of Combing. Removing short fibres, neps and impurities by using combs is called combing. It is the process of separation of long desirable fibres of same length from the short fibres, neps and all remaining foreign materials of the fibre stuck. The fibres also become straight and parallel. Working Principle of Cotton Combing